It Took 50 Years, But Traction Manufacturing Has Changed

Creatures unveils the world’s first molded tail pad — the ‘Proto 1.4’.

Surfers have been historically branded as nature-loving purists but in the era of Greta Thunberg bumper stickers and watershed UN addresses by Sir David Attenborough we now all know how bad we should feel about the boards we ride.

Beau Campi is the Head of Product at Creatures. He also happens to be the Godfather of Mick Fanning’s son, and vice versa. Today, a three-year project of Mick and Beau’s came to life that will likely see a significant change in the design, manufacturing and marketing of traction for years to come.

I found myself wandering out the back of the factory. I looked around and there were these bags, huge plastic bags six feet high by six feet wide, chock full of EVA off-cuts, foam dust, shredded dust, and foam sheets, all of this is waste. My jaw dropped.

– Beau Campi

Creatures have released the world’s first molded tail pad, the Proto 1.4 – which importantly reduces the waste created in the traction manufacturing process from current industry standards by 92%. It is the biggest innovation in traction since Herbie Fletcher first invented the Astrodeck pad in 1976. You can study the pad in detail in this year’s Stab in the Dark with Italo Ferreira – who used 13 Proto 1.4’s to select the winner of this year’s double-blind surfboard test. From April 18, they will be available in these Australian surf stores.

Originally from Cooly, Beau met a 12-year-old Mick shortly after the Fanning’s had moved north from Ballina at a Kirra Boardriders contest. “He was just this white-headed kid that stuck out like dog balls. I remember murmurs from guys like Damon Harvey and others saying ‘the kid rips’. The whole family surfed well, Sean, Ed and even Peter. So Liz (Mumma Fanning) signed the whole family up to Kirra Boardriders, we clicked instantly. All we wanted to do was go surf. Initially, I was much closer with his older brother Sean, even though me and Mick are the same age. It wasn’t until Sean died when we were 16 that we became pretty inseparable,” says Beau. “We were best buds going through that process. And to this day, he’s my godfather to my kids, and likewise, I am for his little boy as well.”

As adults Beau and Mick had mused the idea of creating something together for years. Beau’s previous tenures at Billabong and Volcom as Head of Product meant that couldn’t happen. Interestingly, when Beau did jump ship to Creatures in 2019, one of his first moves was the development of mid-length board bags after observing a rising trend of stretched, voluminous boards on the Gold Coast. Creatures were the first to market with the mid-length coffin, sales flew and Beau had the spinnakers up. His next proposition would be more risky.

“My first trip to the supplier was a huge eye-opener and a pivotal point. We’d just walked the factory floor and seen all the processes: cutting, sanding and routering. We took a little break for lunch and I was on the phone, and I found myself wondering out the back of the factory. I looked around and there were these bags, huge plastic bags six feet high by six feet wide, chock full of EVA off-cuts, foam dust, shredded dust, and foam sheets, all of this is waste. My jaw dropped. I don’t know if it was picked up weekly or monthly, but it was profound how much waste was out there. I couldn’t believe I was so naive to think that this product didn’t have that much waste, especially coming from a product design background,” explains Beau.

“If surfers don’t understand the truth behind traction, then they can’t become believers or understand why there is a different price tag to this traction pad compared to the one next to it. And the truth is ugly.”

As it turns out, the current industry standard sees more than 66% of a traction pad go to waste in manufacturing. The Proto 1.4 by contrast, leaves behind 5%. That’s a 92% reduction in waste product. Fortunately for Beau, the key to the problem was starring him in the face.

“The supplier that we use for traction also makes footwear, whether it’s open-toed footwear or some closed-toed footwear. So they mold some of the insole stuff and some of the outer soles. That was really what got me started. Well, you guys can mold all these things, why can’t we start to mold parts of our traction pad? Why can’t we mold a kick? Why can’t we mold an arch? And they were completely supportive of that and they were up for the challenge,” he explains.

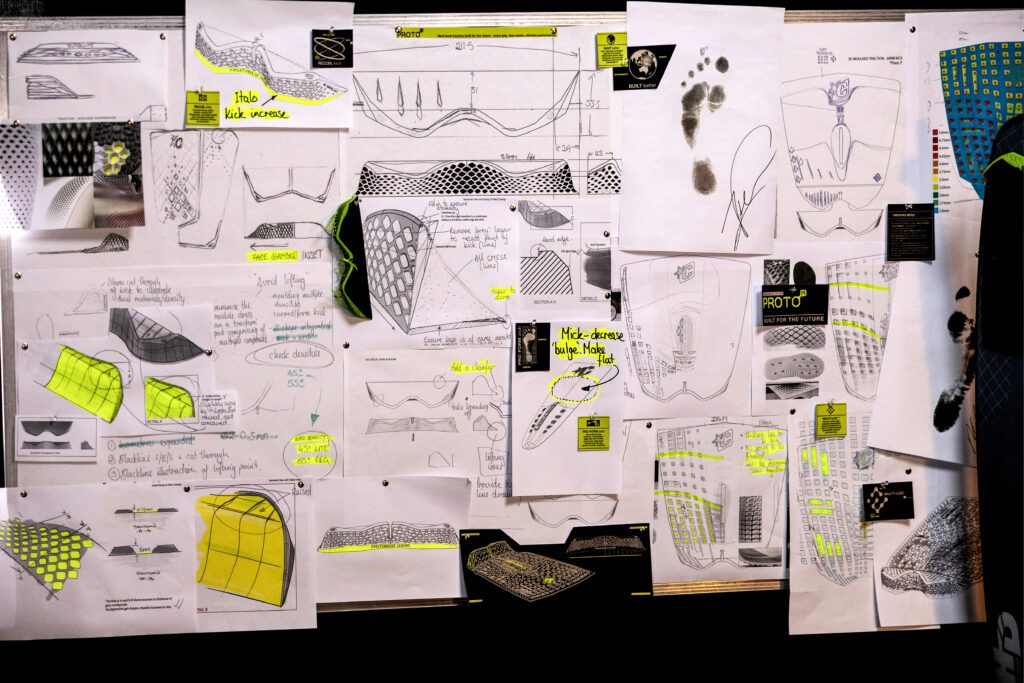

While molding technology has been around since at least Ancient Mesopotamia (4000 BC), it took another 6023 years to realize molding tech could be applied to tail pads. “It definitely felt like a huge risk to me. Selling it to three of the board owners was tough. Luckily they backed me and we got it through a three-year process. Mold casts are expensive and it took us multiple iterations to get here, but we believe in where it’s landed. We’ve changed the way a traction pad is made and consequently changed the by-product and volume of industrial waste. I feel it’s a huge responsibility as a company. If you are not trying to change it, the customers aren’t going to change it for you,” says Beau.

“Italo will jam the outside of his foot right against the tail block when he goes for alley-oops. Mick prefers less ‘grip’ in the front of his tail pad so he can move his feet forward easilier between turns.”

A bad day to be a B Corp is anytime near a recession when the thirst for dollars tends to outweigh the thirst for conscious consumerism. ‘How do you get people to justify paying more for a traction pad?’ I ask Beau – who’s the first to admit not everyone will be convinced by the $100 AUD ($80 USD) price tag.

“Obviously these things get thrown around in marketing meetings and go to market meetings. It’s ‘how can we sell this?’ But in the end where we landed is, we just feel we have to be truthful. We believe in this product, by its performance, the manufacturing efficiency and the reduced by-product. So our goal is just to tell the story of how we make a traction pad in relation to the rest of the industry. If surfers don’t understand the truth behind traction, then they can’t become believers or understand why there is a different price tag to this traction pad compared to the one next to it. And the truth is ugly. If a person comes across any of the Proto 1.4 and learns a little about the current process and what we’re doing, and then they see a price tag and they don’t like it because of that, at least they’ve understood the issue and we’ve provided them with knowledge about how a traction pad’s made, and how we’re doing it differently. And maybe in two or three years time when we’re rolling this out in a wider space, they will buy the pad. I don’t think this is going to explode overnight. It’s going to be a slow-burn. But we believe wholly in it, that it’s going to make a total difference to the product, and also the surfing performance as well.”

“There was no bullshit, trying to blow smoke up my ass or piss in my pocket. He was telling me straight if it sucked or not, and where we needed to improve. He’s constructive about the way he goes about things.

– Beau on his working relationship with Mick

We’ve banged on about Mick’s work ethic quite a bit at Stab, less so about his hawkish attention to detail. His decades-old friendship with Beau meant he could deliver his feedback with brutal honesty. “There was no bullshit, trying to blow smoke up my ass or piss in my pocket. He was telling me straight if it sucked or not, and where we needed to improve. He’s constructive about the way he goes about things. ‘Yeah, it sucks, but this actually felt really good’ or ‘this really worked’, or ‘this actually surprised me’. He is so specific, it’s unbelievable. He will pick on the weight of a pad. If the base of the pad is too thick, he doesn’t have that sensitivity and responsiveness, he’ll go, ‘this pad’s too thick’. Because the molding removes most of the room for human error, it’s pretty much to his dream of making it precise. You no longer have to worry about a manufacturer hand sanding the bevels on the kick, the routering of the actual traction, making sure that the bases are an exact 2.5 millimeter at the base. Because of the design, everything fits together like a jigsaw puzzle.”

An interesting tidbit to come out of Creature’s R&D is how specific surfers move their feet. Beau admits, “I’ve never looked at so much back foot surfing in the last two or three years in my life”. Ethan Ewing, for example, likes to dig his big toe in on frontside bottom-turns. Italo will jam the outside of his foot right against the tail block when he goes for alley-oops. Mick prefers less ‘grip’ in the front of his tail pad so he can move his feet forward easilier between turns. All of this information has been factored into the design of the Proto 1.4’s countless features from it’s bevels, pattern, angles, grooves and height profiles.

A nice perk of work at Stab is surf gear passes through the doors rather frequently. So while I will not be buying a Proto 1.4 myself anytime soon, I will absolutely be rinsing their next shipment to the office.

Comments

Comments are a Stab Premium feature. Gotta join to talk shop.

Already a member? Sign In

Want to join? Sign Up